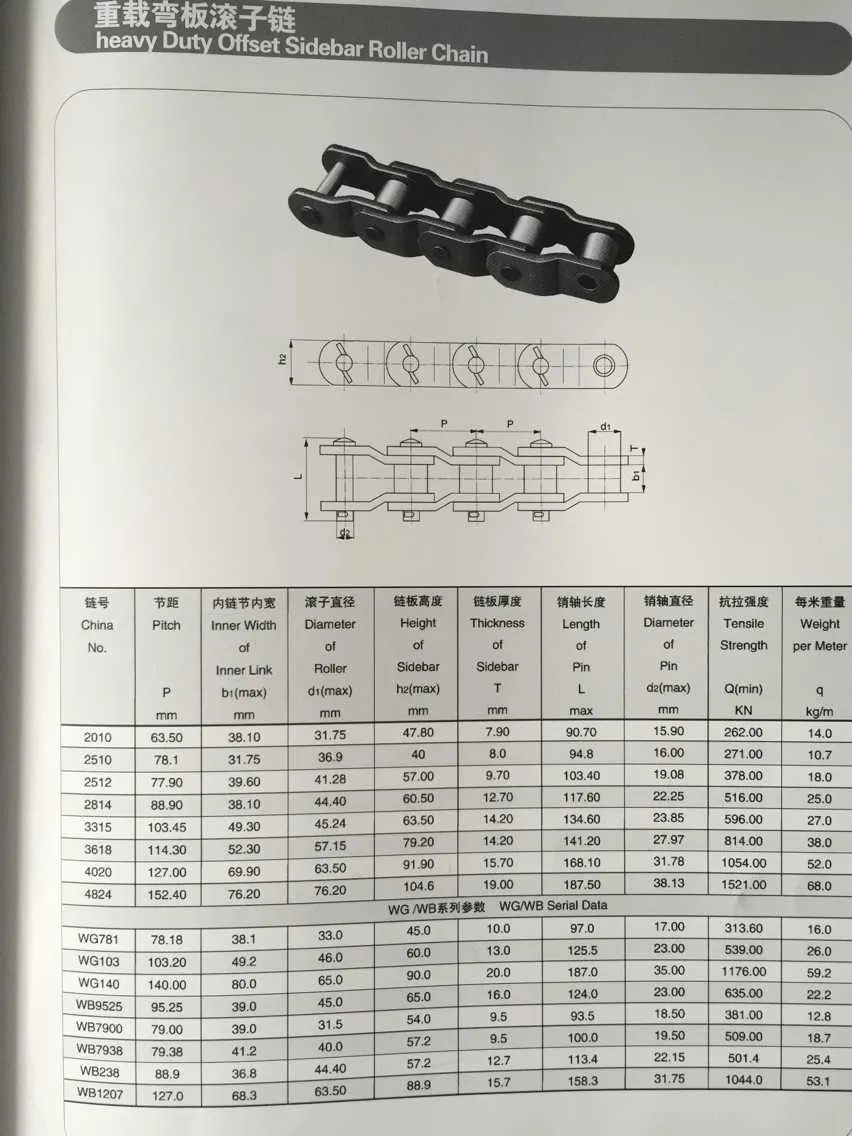

Heavy Duty Offset Sidebar Roller Chain

Heavy Duty Offset Sidebar Roller ChainThe heavy duty offset sidebar roller chain is designed for drive and traction purposes, and is commonly used on mining equipment, grain processing equipment, as well as equipment sets in steel mills. It is processed with high strength, impact resistance, and wea......

Send Inquiry

Product Description

Heavy Duty Offset Sidebar Roller Chain

The heavy duty offset sidebar roller chain is designed for drive and traction purposes, and is commonly used on mining equipment, grain processing equipment, as well as equipment sets in steel mills. It is processed with high strength, impact resistance, and wearing resistance, so as to ensure safety in heavy duty applications.

Design and Processing Advantages

1. Made of medium carbon steel, the offset sidebar roller chain undergoes processing steps like heating, bending, as well as cold pressing after annealing.

2. The pin hole is created by impact extrusion, which increases the inner surface smoothness for the hole. Thus, the matching area between the sidebar and the pin is increased, and the pins offer higher protection against heavy loads.

3. The integral heat treatment for the chain plates and rollers ensures high tensile strength. The pins additionally undergo high-frequency induction heating for the surface after integral heat treatment, ensuring high strength, high surface hardness, and wearing resistance as well. The surface carburizing treatment for the bushings or sleeves guarantees high tensile strength, superb surface hardness, and improved impact resistance. These make sure the heavy duty transmission chain has extended service life.