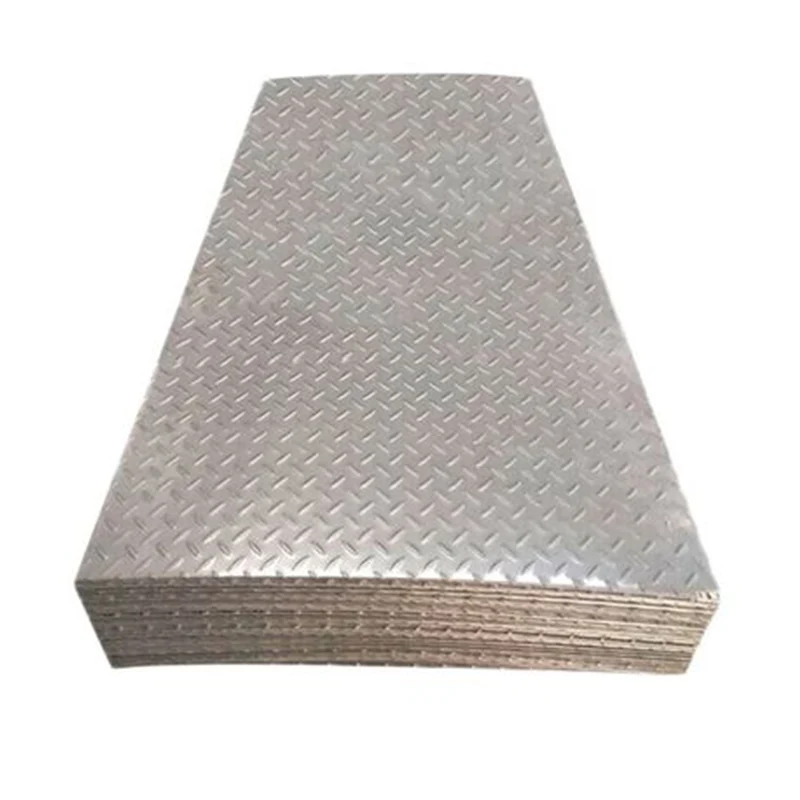

how to make high-quality Carbon Steel Plate

2025-04-25

Making high-quality carbon steel plate involves precise control over materials, temperature, and processing techniques. Here’s a simplified step-by-step breakdown of how it's made in an industrial setting:

1. Raw Material Selection

Iron Ore or Scrap Steel: The base material, either freshly mined iron ore or recycled scrap steel.

Carbon Content: The carbon content usually ranges from:

Low Carbon Steel: < 0.3%

Medium Carbon Steel: 0.3–0.6%

High Carbon Steel: > 0.6%

The percentage affects the steel’s hardness, ductility, and strength.

2. Melting (Steelmaking Process)

Typically done in a Basic Oxygen Furnace (BOF) or Electric Arc Furnace (EAF):

Raw materials are melted at ~1600°C.

Oxygen is blown into the molten iron to reduce carbon content and remove impurities (like sulfur and phosphorus).

3. Refining and Alloying

Add carbon and alloying elements (if required) to achieve the desired steel composition.

Use Ladle Refining Furnace (LRF) or Vacuum Degassing to ensure high purity and control microstructure.

4. Casting

The molten steel is then solidified into slabs using:

Continuous Casting: Molten steel is poured into a mold and continuously cooled to form a solid slab.

Ingot Casting (less common for plates): Steel is cast into large molds and cooled.

5. Hot Rolling

Slabs are reheated to ~1100–1250°C in a reheat furnace.

Then passed through a hot rolling mill to reduce thickness and improve uniformity.

This shapes the steel into plates and improves grain structure and mechanical properties.

6. Controlled Cooling or Heat Treatment

Controlled Cooling on the runout table to develop desired mechanical properties.

Optional heat treatment (e.g., normalizing, quenching & tempering) depending on the desired plate grade.

7. Cold Finishing (if required)

Plates may be further cold rolled for tighter tolerances and surface finish.

Pickling: Removes scale from hot rolling using acid.

Shot blasting and grinding: To improve surface quality.

8. Testing and Inspection

Ultrasonic Testing, X-ray, Tensile Testing, Hardness Tests, and Metallurgical Analysis to ensure quality.

Conformance to standards like ASTM, EN, JIS, or ISO depending on application.

9. Finishing & Packaging

Cut to length or width.

Edges trimmed or beveled.

Surface coated with anti-corrosion materials like oil, paint, or zinc.

Plates are marked, bundled, and shipped.

Wanhetong Steel (shandong) Co., Ltd is one of China's steel companies with a long history and profound heritage. It was established in July 2021. The factory produces 10 million tons of steel every month and supplies global customers. We mainly produce carbon steel, galvanized, color-coated, color-coated roof panels and other products. If you are interested in our products or have any questions, please feel free to contact us.