What Are Metal Stamping Die Parts and Why Do They Matter in Precision Manufacturing?

2025-12-26

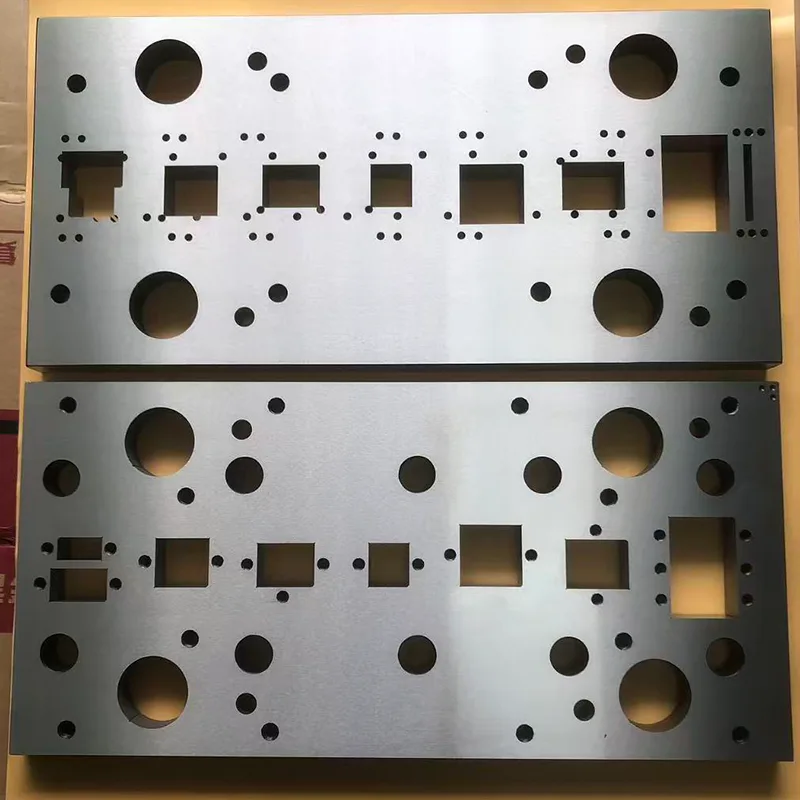

Metal stamping is one of the most efficient and scalable manufacturing processes for producing high-precision metal components across industries such as automotive, electronics, medical devices, and industrial equipment. At the heart of this process are Metal Stamping Die Parts, which directly determine product accuracy, consistency, and production efficiency. Without well-designed and precisely manufactured die parts, even the most advanced stamping presses cannot achieve stable, high-quality output.

Understanding Metal Stamping Die Parts

Metal Stamping Die Parts refer to the critical components that make up a metal stamping die set. These parts work together to shape, cut, bend, or form metal sheets into specific geometries. Common die parts include punches, die blocks, guide pins, stripper plates, and springs. Each component must meet strict dimensional and material requirements to ensure durability and repeatability in high-volume production.

At Shenzhen Xincheng Precision Technology Co., Ltd., we specialize in manufacturing high-precision metal stamping die parts with tight tolerances, long service life, and excellent interchangeability, supporting both standard and customized stamping solutions.

Key Functions of Metal Stamping Die Parts

The primary role of metal stamping die parts is to ensure accurate forming and cutting during the stamping process. Their main functions include:

-

Positioning and guiding metal sheets accurately

-

Cutting or shaping materials according to design specifications

-

Maintaining alignment during high-speed stamping

-

Reducing wear and deformation over long production cycles

Main Types of Metal Stamping Die Parts

| Die Part Type | Function | Importance |

|---|---|---|

| Punch | Cuts or forms the metal | Determines shape accuracy |

| Die Block | Supports material shaping | Ensures dimensional stability |

| Guide Pin | Aligns upper and lower dies | Improves consistency |

| Stripper Plate | Removes material from punch | Enhances efficiency |

| Spring | Controls pressure and movement | Extends die life |

Effects of High-Quality Die Parts in Use

Using premium Metal Stamping Die Parts significantly improves production outcomes. High-quality die components reduce burrs, minimize scrap rates, and allow for faster cycle times. In real production environments, this leads to more stable output, lower maintenance costs, and improved overall equipment efficiency (OEE).

Why Metal Stamping Die Parts Are So Important

The importance of metal stamping die parts lies in their direct impact on product quality and manufacturing cost. Poor-quality die parts can cause misalignment, excessive wear, frequent downtime, and inconsistent products. In contrast, precision-engineered die parts ensure:

-

Longer tool life

-

Consistent product dimensions

-

Lower defect rates

-

Higher production efficiency

This is why many global manufacturers choose Shenzhen Xincheng Precision Technology Co., Ltd. as their long-term partner for reliable and cost-effective stamping die solutions.

Professional Manufacturing with Marketing Value

Beyond technical performance, professionally manufactured metal stamping die parts also add marketing value. Stable quality, fast delivery, and customization capabilities strengthen customer trust and brand reputation. Our company combines advanced CNC machining, strict quality control, and experienced engineering teams to deliver die parts that meet international standards and exceed customer expectations.

Conclusion

In modern manufacturing, Metal Stamping Die Parts are not just tooling components—they are strategic assets that influence efficiency, quality, and competitiveness. Choosing the right supplier ensures smoother production and long-term cost savings. If you are looking for precision, reliability, and professional support, Shenzhen Xincheng Precision Technology Co., Ltd. is ready to be your trusted partner.

For more details or customized solutions, contact us today and let us help you optimize your metal stamping projects.