What Are PCD Inserts and Why Are They Essential for Modern Machining?

2025-12-22

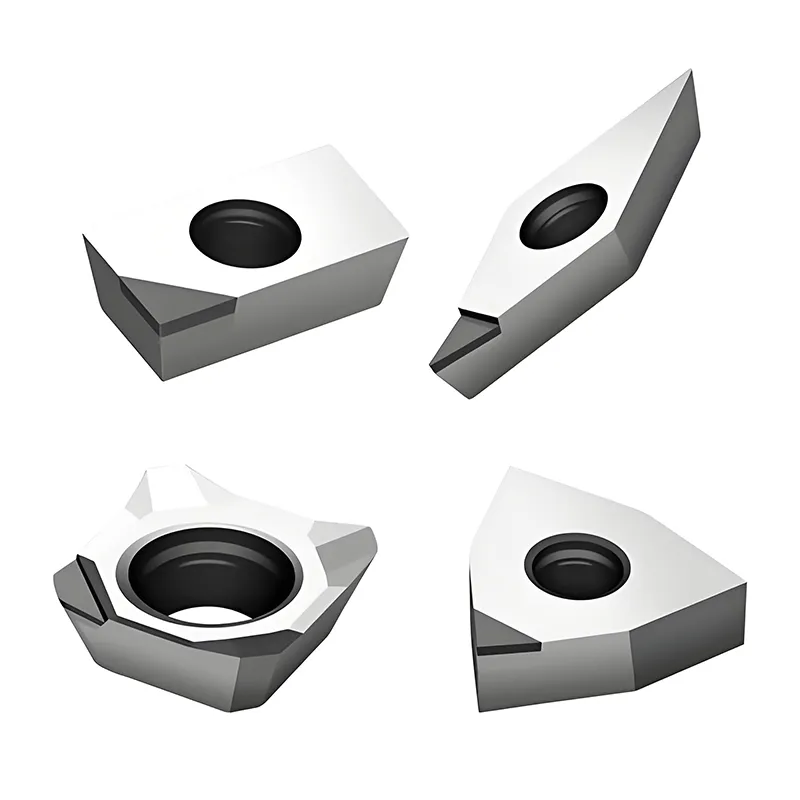

In today's high-precision machining industry, PCD Inserts have become a cornerstone for efficiency and accuracy. As a manufacturing professional at Ningbo Wonderful Numerical Control Technology Co., Ltd., I have personally seen how integrating PCD inserts into operations transforms production quality and reduces tool wear. These inserts, made from Polycrystalline Diamond, offer unmatched hardness and thermal conductivity, making them ideal for cutting non-ferrous metals, composites, and abrasive materials. The versatility and long lifespan of PCD Inserts make them a go-to solution for advanced machining challenges.

Why Should I Choose PCD Inserts Over Traditional Carbide Inserts?

I often get asked this question: "Why should I switch from carbide inserts to PCD Inserts?" The answer is simple. Unlike conventional carbide, PCD inserts maintain sharp cutting edges for longer periods, significantly reducing downtime for tool changes. They also provide superior surface finish and precision, which is critical in industries like automotive, aerospace, and electronics.

Here's a quick comparison for clarity:

| Feature | Carbide Inserts | PCD Inserts |

|---|---|---|

| Hardness | Moderate | Extremely High |

| Wear Resistance | Medium | Excellent |

| Suitable Materials | Steel, Stainless | Aluminum, Copper, Composites |

| Tool Life | Shorter | Longer |

| Surface Finish | Good | Superior |

How Do PCD Inserts Improve Machining Efficiency?

Another common question I receive is: "How exactly can PCD Inserts boost efficiency?" By reducing tool wear, PCD inserts minimize machine stoppages for replacements. Their thermal stability also allows for higher cutting speeds without compromising the workpiece quality. In my experience, switching to PCD Inserts can increase production output by up to 30% while maintaining exceptional dimensional accuracy.

The Importance of Choosing the Right PCD Insert

Selecting the correct PCD insert is crucial. Here are the main factors to consider:

-

Material of the workpiece: Different PCD grades suit different materials.

-

Cutting speed and feed rate: PCD performs best at optimized speeds.

-

Insert geometry: Positive or negative rake angles affect chip flow and surface finish.

-

Machine compatibility: Ensure inserts fit your CNC tools precisely.

At Ningbo Wonderful Numerical Control Technology Co., Ltd., we provide tailored solutions to match your specific machining needs.

What Are the Key Benefits of Using PCD Inserts?

I often ask myself, "What makes PCD Inserts indispensable in modern manufacturing?" The benefits are multi-fold:

-

Extended Tool Life: Reduces replacement frequency and saves cost.

-

High Precision: Produces superior surface finishes consistently.

-

Efficiency: Supports higher cutting speeds and reduces production cycles.

-

Versatility: Suitable for a wide range of non-ferrous metals and composites.

Incorporating PCD Inserts into your machining process ensures better performance, lower operational costs, and higher production standards.

Conclusion

In conclusion, PCD Inserts are no longer an optional upgrade—they are a necessity for companies seeking efficiency and precision in high-volume manufacturing. At Ningbo Wonderful Numerical Control Technology Co., Ltd., we provide a wide range of high-quality PCD inserts designed for optimal performance and reliability. If you're looking to enhance your machining capabilities and achieve superior results, contact us today to explore our solutions tailored to your production needs.