What Are the Different Types of Casting Balls?

2025-09-15

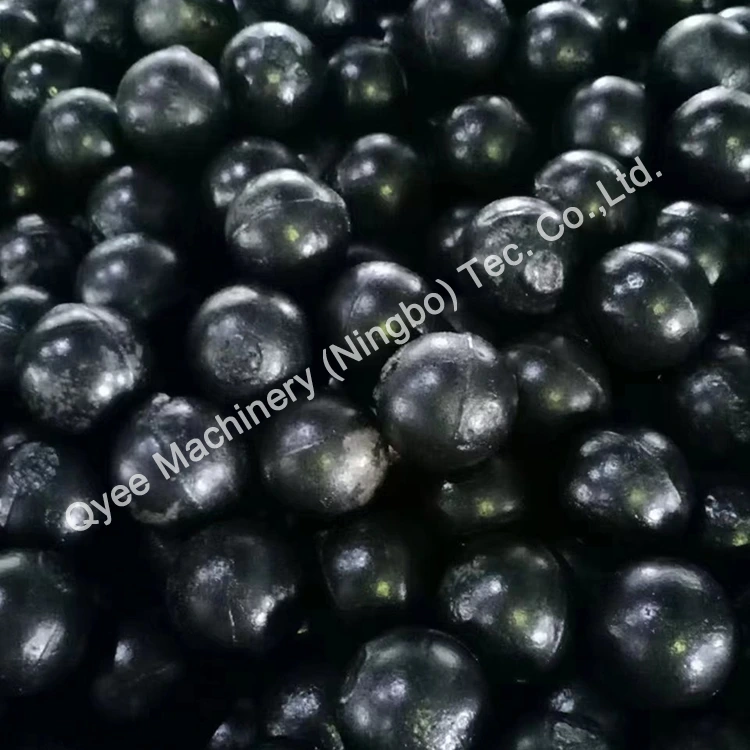

Casting balls are specialized metal components manufactured through various foundry processes to achieve specific properties like high wear resistance, impact strength, and structural integrity. They are critical consumables in industries such as mining, milling, and precision manufacturing. Understanding the different types is essential for selecting the right grinding media or functional component for your operation, impacting both efficiency and cost-effectiveness.

Primary Types of Casting Balls Based on Material

The performance of a casting ball is predominantly determined by its material composition and the manufacturing process. Our factory produces several key types to meet diverse industrial demands.

1. High Chrome Casting Balls: These are premium-grade balls known for exceptional hardness and wear resistance. They contain a high percentage of chromium, which forms hard carbides, resulting in a lower wear rate and reduced consumption in grinding mills. They are ideal for abrasive environments.

2. Chrome Casting Balls: Offering a balance between performance and cost, these balls have a moderate chromium content. They provide good hardness and are a cost-effective solution for many standard grinding applications.

3. Low Chrome Casting Balls: With a lower chromium content, these balls are an economical choice for less demanding operations where the highest level of abrasion resistance is not critical.

4. Cast Iron Balls: Made from grey or white cast iron, these are general-purpose balls used in specific applications where cost is a primary driver, though they offer lower impact resistance and higher breakage rates compared to alloyed balls.

Key Product Parameters and Specifications

Selecting the right casting ball requires careful attention to technical specifications. Our Casting Parts are engineered to precise standards to ensure consistent performance and reliability in the field.

| Parameter | Specification | Importance |

| Hardness | ≥ 58 HRC (High Chrome) | Determines wear resistance and longevity |

| Chromium Content | 10% - 28% | Directly influences corrosion and abrasion resistance |

| Impact Toughness | ≥ 4 J/cm² | Measures resistance to breaking or chipping upon impact |

| Diameter Tolerance | ± 1.0 mm | Ensures consistent size for efficient grinding operation |

| Breakage Rate | < 0.5% | Indicates product reliability and structural integrity |

Other critical parameters include chemical composition (C, Si, Mn, Cu, Mo), micro-structure, and surface quality. Each batch of our Casting Parts undergoes rigorous testing to verify these parameters, ensuring they meet our high standards before they reach the customer.

Frequently Asked Questions (FAQs)

Q1: What is the main difference between high chrome and low chrome casting balls?

The main difference lies in their chromium content, which directly dictates their performance and cost. High chrome balls (containing 18-28% chromium) offer superior hardness, excellent wear resistance, and a very low breakage rate, making them ideal for the most abrasive and demanding milling conditions. Low chrome balls (containing 1-3% chromium) are harder than cast iron but offer less wear resistance than high-chrome alternatives, serving as a more economical choice for less severe operations.

Q2: How do I choose the right type of casting ball for my application?

Choosing the right type depends on several factors related to your specific operation. Key considerations include the hardness and abrasiveness of the material being ground, the operating speed and diameter of your mill, and your overall cost-efficiency goals. For highly abrasive ores, our high chrome Qyee balls are typically the most cost-effective long-term choice due to their low consumption rate. For less abrasive materials or where initial cost is a major concern, mid or low-chrome options may be suitable. Our technical team can provide a detailed recommendation based on your process parameters.

Why Choose Our Casting Parts?

At Qyee, we are committed to manufacturing high-performance casting balls that deliver unmatched durability and value. Our advanced production facilities and strict quality control processes ensure that every product meets precise specifications. We leverage our expertise to provide solutions that enhance operational efficiency and reduce total grinding costs for our clients. For a detailed consultation and to find the ideal Casting Parts for your needs, contact Qyee Machinery (Ningbo) Tec. Co., Ltd. today. Let our expertise drive your productivity.