What is a Resin Bond Diamond Grinding Wheel?

2025-09-10

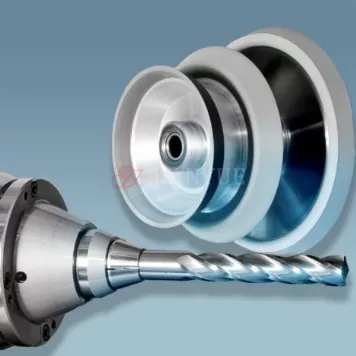

A resin bond diamond grinding wheel is an abrasive tool where synthetic diamond grains, the hardest material known, are held within a matrix composed of a synthetic resin bond. This combination creates a wheel that is exceptionally effective for grinding hard, brittle materials like carbide, ceramics, glass, and semiconductors. The resin bond is relatively softer than metal or vitrified bonds, which allows the wheel to wear in a way that constantly exposes fresh, sharp diamond particles. This self-sharpening action ensures a cooler cut and produces a superior surface finish, making it a preferred choice for precision grinding operations.

Key Product Parameters and Features

Our factory meticulously engineers each resin bond diamond grinding wheel to meet precise specifications. The performance and application of the wheel are determined by several critical parameters:

1. Abrasive Diamond Quality: We use high-grade synthetic diamonds, selected for their toughness and cutting ability. The grain size is carefully chosen based on the required surface finish; finer grits for polishing and coarser grits for stock removal.

2. Bond Type: The phenolic resin formula is a proprietary blend developed in our facility. This formulation is engineered to provide the optimal balance between hardness and wear resistance, allowing the diamond particles to be released effectively without premature shedding.

3. Concentration: This indicates the amount of diamond abrasive present in the bond. A higher concentration number means more diamonds are available for grinding, increasing the wheel's lifespan and aggressiveness. Our standard concentrations are tailored for both longevity and cutting speed.

4. Wheel Hardness (Grade): The hardness of the resin bond determines how quickly the wheel wears. A softer grade wears faster, exposing new diamonds more quickly for cooler grinding of hard materials, while a harder grade is better for form holding and grinding softer materials.

To better understand how these parameters interact, refer to the following table:

| Parameter | Description | Impact on Performance |

| Diamond Grit Size | The size of the abrasive particles. | Coarser grits (e.g., 80/100) remove material faster but leave a rougher finish. Finer grits (e.g., 400/500) produce a smoother surface. |

| Concentration | The amount of diamond in the bond matrix. | Standard concentration is 100 (25% volume). Higher concentrations (e.g., 125) offer longer life. Lower concentrations (e.g., 75) are more aggressive. |

| Bond Hardness | The resistance of the resin bond to wear. | A softer bond breaks down faster, ideal for hard materials as it keeps the wheel sharp. A harder bond maintains its shape for precision form grinding. |

Applications of Resin Bond Diamond Grinding Wheels

The unique properties of the resin bond diamond grinding wheel make it indispensable in several industries. Its primary use is in the sharpening and manufacturing of carbide tools and inserts, where its cool cutting action prevents thermal damage to the delicate carbide edges. Furthermore, it is the wheel of choice for finishing applications on ceramic components, optical glass, and in the electronics industry for silicon wafer processing. The versatility of our JIANYUE wheels is a result of our deep understanding of these diverse application needs.

Frequently Asked Questions (FAQ)

Q1: What is the main advantage of a resin bond over other bond types?

The primary advantage of a resin bond diamond grinding wheel is its ability to provide a exceptionally fine surface finish due to its resilient and somewhat elastic nature. It operates at lower temperatures than metal bond wheels, which minimizes the risk of thermal damage like micro-cracks in the workpiece. This makes it perfect for final precision grinding and sharpening.

Q2: How should I store and handle my resin bond diamond grinding wheel?

Proper storage is crucial for maintaining wheel integrity. Store wheels in a dry, temperature-controlled environment to prevent the resin bond from absorbing moisture, which can lead to imbalance. Always handle wheels with care to avoid chipping or cracking. Mount them on the correct flange size and ensure they are properly balanced before use to achieve optimal performance and safety. Following our factory's guidelines will ensure you get the longest service life from your tool.

Why Choose Us?

Choosing the right grinding wheel is critical for achieving optimal results in precision grinding. The Resin Bond Diamond Grinding Wheel stands out for its excellent finishing capabilities and cool operation. At JIANYUE, we combine advanced manufacturing techniques with rigorous quality control to produce wheels that meet the highest standards of performance and reliability. For professionals who require consistency and quality, trusting a proven brand is essential. Explore the full range of high-performance grinding solutions available at JIANYUE Diamond Wheel Co., Ltd. Contact us today to find the perfect wheel for your specific application and experience the JIANYUE difference in quality and precision.