What Makes Precast Concrete Moulds Essential for Modern Construction?

2025-12-31

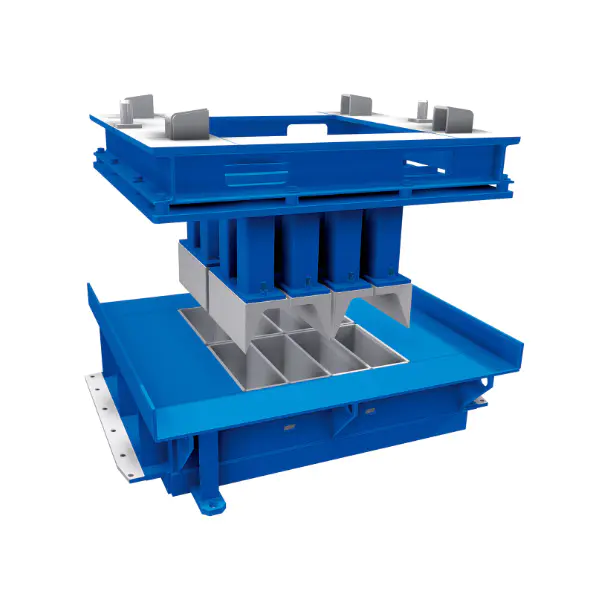

In today's fast-evolving construction industry, efficiency, precision, and sustainability are no longer optional—they are fundamental requirements. Precast Concrete Moulds play a critical role in meeting these demands by enabling manufacturers to produce high-quality concrete components in a controlled environment. From infrastructure projects to residential and commercial buildings, precast solutions are redefining how structures are designed and delivered. As a professional mould manufacturer, Fujian Quangong Mould Co.,Ltd integrates advanced engineering with practical industry experience to provide reliable mould systems that support long-term construction success.

The Role of Precast Concrete Moulds in Construction

Precast Concrete Moulds are specially designed forms used to shape concrete elements such as blocks, pipes, slabs, and wall panels before they are transported to the construction site. Their core role is to ensure dimensional accuracy, surface quality, and structural consistency across large production volumes.

Key roles include:

-

Shaping concrete products with precise dimensions

-

Improving surface finish and aesthetic quality

-

Enabling mass production with consistent standards

-

Reducing on-site construction time

Why Precast Concrete Moulds Matter

The importance of Precast Concrete Moulds goes far beyond simple forming. They directly influence production efficiency, cost control, and final product performance.

Main Reasons for Their Importance

-

Production Efficiency – Standardized moulds accelerate casting cycles and reduce labor costs.

-

Quality Assurance – Controlled factory environments ensure uniform strength and durability.

-

Cost Effectiveness – Long service life of steel moulds lowers long-term manufacturing expenses.

-

Sustainability – Reduced material waste and energy-efficient production processes.

At Fujian Quangong Mould Co.,Ltd, moulds are engineered to withstand high-frequency vibration and intensive use, ensuring stable performance even under demanding production conditions.

Practical Effects of Using Precast Concrete Moulds

Using high-quality Precast Concrete Moulds delivers measurable results throughout the project lifecycle.

-

Faster project timelines

-

Reduced rework and material waste

-

Higher load-bearing capacity of finished components

-

Improved safety due to factory-controlled production

These effects make precast technology particularly suitable for large-scale infrastructure, industrial buildings, and urban housing projects.

Precast Concrete Moulds vs Traditional On-Site Formwork

| Aspect | Precast Concrete Moulds | Traditional Formwork |

|---|---|---|

| Production Location | Factory controlled | On-site |

| Quality Consistency | High | Variable |

| Labor Requirement | Lower | Higher |

| Construction Speed | Fast | Slower |

| Long-Term Cost | Optimized | Often higher |

This comparison highlights why more contractors and developers are shifting toward precast systems.

Why Choose Fujian Quangong Mould Co.,Ltd

As an experienced manufacturer, Fujian Quangong Mould Co.,Ltd focuses on precision machining, durable materials, and customized solutions. Our Precast Concrete Moulds are compatible with advanced block-making and precast production lines, ensuring seamless integration and high productivity.

Our advantages include:

-

Customized mould design

-

High-strength alloy steel materials

-

Strict quality control processes

-

Professional technical support

The Strategic Value of Precast Concrete Moulds

Precast Concrete Moulds are not just tools—they are strategic assets that directly impact construction quality, efficiency, and profitability. By choosing a reliable mould supplier, manufacturers can gain a competitive edge in an increasingly demanding market.

If you are looking to upgrade your precast production or explore customized mould solutions, Fujian Quangong Mould Co.,Ltd is ready to support your goals. Contact us today to learn how our professional Precast Concrete Moulds can help you achieve higher efficiency and long-term value.