Why Choose a Small-Scale AAC Block Plant for Sustainable Construction?

2025-12-24

Autoclaved Aerated Concrete has become a core material for modern green buildings, and a Small-Scale AAC Block Plant is often the smartest entry point for manufacturers who want flexibility without excessive investment. Designed for regional markets and controlled output, this solution balances production efficiency, energy savings, and consistent quality while responding quickly to local construction demand.

What Is the Role and Function of a Small-Scale Solution?

A Small-Scale AAC Block Plant is engineered to produce lightweight AAC blocks using cement, lime, sand, water, and aluminum powder through a precise aeration and autoclaving process. Its core role is to transform raw materials into high-performance building blocks with excellent insulation and fire resistance, but on a footprint and budget suitable for small to medium enterprises.

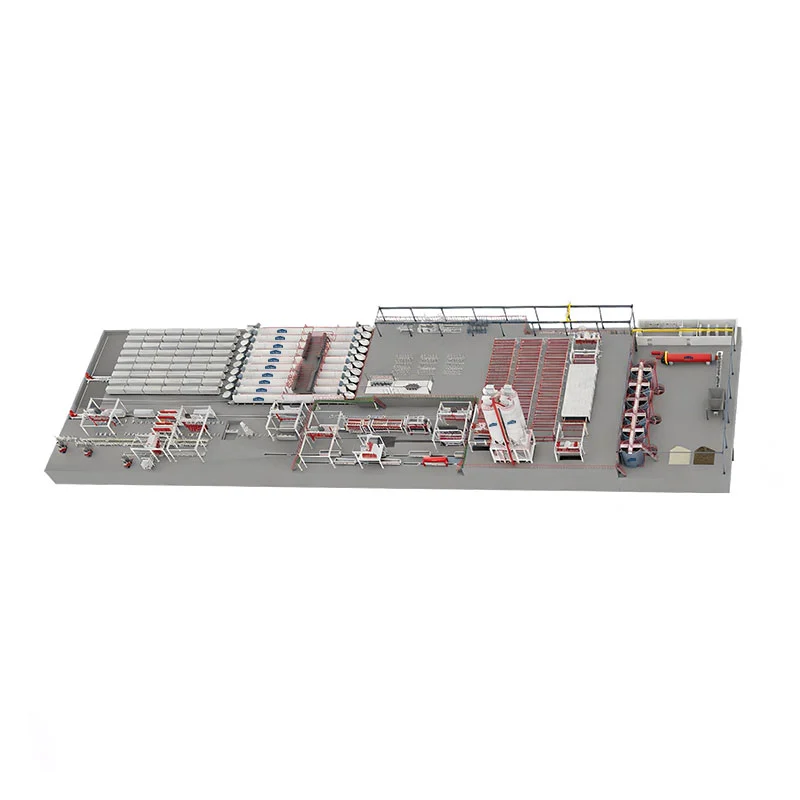

From a functional perspective, such a plant integrates batching, mixing, cutting, and autoclaving systems in a compact layout. The result is stable production, lower labor intensity, and predictable operating costs.

How Effective Is It in Real Applications?

The practical use effect of a Small-Scale AAC Block Plant is reflected in faster installation on job sites, reduced structural load, and improved thermal performance of buildings. Contractors benefit from easier handling, while developers gain long-term energy savings.

Key Use Effects

-

Reduced material waste

-

Faster block curing and delivery

-

Improved building energy efficiency

Small-Scale vs Large-Scale AAC Plants

| Item | Small-Scale Plant | Large-Scale Plant |

|---|---|---|

| Initial Investment | Lower | Very High |

| Flexibility | High | Medium |

| Market Focus | Local / Regional | National / Export |

| Operating Risk | Controlled | Higher |

This comparison shows why many startups prefer a Small-Scale AAC Block Plant before expanding capacity.

Three Key Questions Answered

Q1: Why is this plant important for new manufacturers?

A1: I believe it lowers entry barriers while ensuring professional-grade AAC production, making it ideal for first-time investors.

Q2: How does technology impact production quality?

A2: We design integrated systems at ZENITH Maschinenfabrik GmbH that maintain density accuracy and cutting precision throughout the process.

Q3: What makes it a long-term strategic asset?

A3: I recommend it because scalability allows gradual upgrades without disrupting existing operations.

Why It Matters in Today's Market

The importance of this solution lies in sustainability, cost control, and market responsiveness. With urbanization accelerating and green building standards tightening, manufacturers need adaptable equipment that delivers certified quality without excessive risk.

Backed by German engineering expertise, ZENITH Maschinenfabrik GmbH provides tailored solutions that combine automation, durability, and strong after-sales support—turning compact AAC plants into reliable profit centers.

If you are planning to enter or optimize AAC block production, now is the time to explore a proven, efficient setup. To learn how our solutions can match your market goals and budget, contact us today for a professional consultation.