Why Is the Brazed Diamond Grinding Wheel the Best Choice for Precision Grinding?

2025-10-11

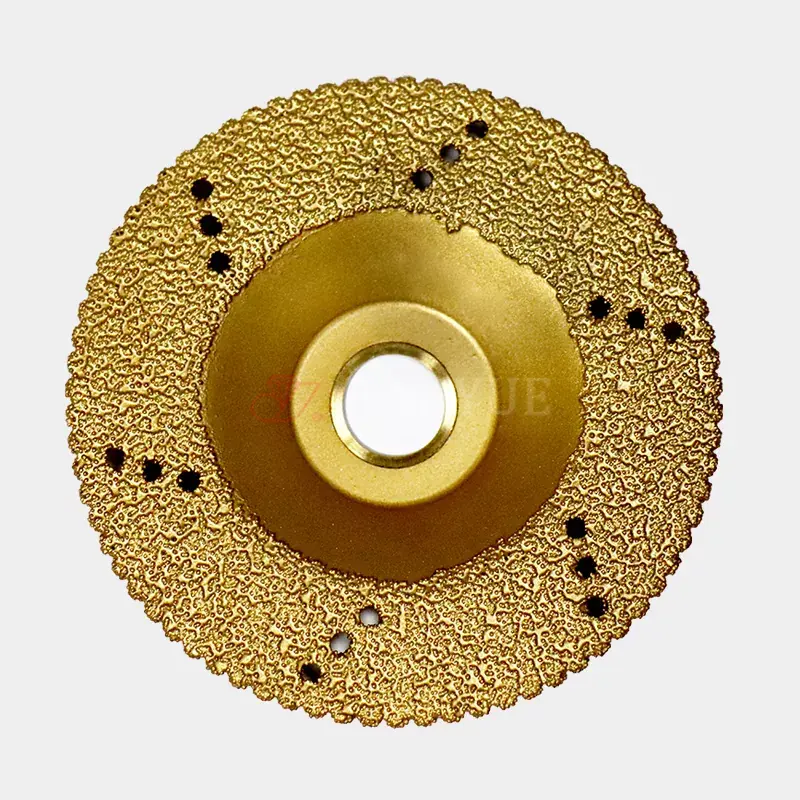

When it comes to precision grinding and cutting applications, choosing the right tool determines efficiency, accuracy, and longevity. Among the many grinding tools available today, the Brazed Diamond Grinding Wheel stands out as one of the most durable and high-performing solutions for various industrial applications. As someone deeply involved in the grinding and polishing industry, I've found that this wheel not only enhances productivity but also ensures consistent performance even under demanding conditions.

What Is a Brazed Diamond Grinding Wheel?

A Brazed Diamond Grinding Wheel is a high-efficiency tool where diamond grits are firmly bonded to the wheel's surface through a vacuum brazing process. Unlike traditional electroplated or resin-bond wheels, brazing technology provides a stronger bond between diamond and substrate, resulting in higher cutting efficiency, sharper grinding performance, and longer tool life.

This wheel is often used in grinding hard materials such as:

-

Tungsten carbide

-

Ceramics

-

Stone and granite

-

Glass

-

Concrete and composites

Below is a simple parameter table for a better understanding of its specifications:

| Parameter | Description |

|---|---|

| Material | Industrial diamond + steel/aluminum base |

| Bond Type | Vacuum brazed |

| Grit Size | 40#–400# |

| Working Thickness | 3–10 mm |

| Application | Grinding, shaping, edge trimming |

| Brand | QuanZhou JianYue Diamond Wheel Co., LTD |

The Function and Performance

The primary function of a Brazed Diamond Grinding Wheel is to remove material quickly and smoothly, offering a superior surface finish without burning or chipping. It maintains a stable grinding performance due to its unique single-layer diamond exposure, which allows for better heat dissipation and less clogging.

In actual use, I noticed that the wheel provides a faster cutting speed and better control than resin or sintered wheels. This is particularly valuable when working on high-hardness materials where conventional wheels tend to wear out quickly.

Why Is It So Effective?

The effectiveness of the Brazed Diamond Grinding Wheel lies in the way the diamond grits are bonded. Vacuum brazing forms a strong metallurgical connection, ensuring each diamond particle remains exposed and active during operation. This leads to:

-

Higher Grinding Efficiency — Each diamond edge participates in cutting.

-

Longer Lifespan — Less frequent wheel replacement reduces production cost.

-

Excellent Heat Resistance — Prevents thermal damage to materials.

-

Superior Precision — Ideal for delicate edges or surfaces.

Its Importance in Modern Industry

In modern manufacturing, precision and consistency are key. The Brazed Diamond Grinding Wheel is widely used in industries such as aerospace, construction, semiconductor, and stone processing. Its versatility helps manufacturers reduce downtime, save on costs, and achieve better finishing quality.

For example, QuanZhou JianYue Diamond Wheel Co., LTD has been providing customized solutions for clients who demand extreme precision and performance. Their advanced vacuum brazing technology and strict quality control ensure that every wheel delivers reliability and professional-grade results.

Q1: Why should I choose a Brazed Diamond Grinding Wheel instead of a resin-bond one?

A1: Because the brazed type offers a stronger bond between diamond and substrate, leading to a higher material removal rate, sharper edges, and better durability. Unlike resin wheels that lose shape quickly, the brazed wheel maintains consistent cutting performance for a longer time.

Q2: How does QuanZhou JianYue Diamond Wheel Co., LTD ensure product quality?

A2: As a professional manufacturer, QuanZhou JianYue Diamond Wheel Co., LTD applies advanced vacuum brazing equipment and precision inspection systems. Every Brazed Diamond Grinding Wheel undergoes strict quality checks for balance, hardness, and diamond exposure rate to guarantee stable and efficient performance for global users.

Q3: Can I use a Brazed Diamond Grinding Wheel for both wet and dry applications?

A3: Yes, you can. These wheels are designed to handle both wet and dry grinding conditions. However, for longer tool life and better cooling, it's recommended to use wet grinding whenever possible. This reduces frictional heat and enhances surface smoothness.

Key Advantages Summary

| Feature | Benefit |

|---|---|

| High bonding strength | Stable and long-lasting performance |

| Sharp cutting edge | Faster grinding, reduced effort |

| Heat resistance | Avoids material burning |

| Versatile application | Suitable for multiple materials |

| Eco-friendly | No resin fumes or dust pollution |

Conclusion

In conclusion, the Brazed Diamond Grinding Wheel represents a breakthrough in modern grinding technology — combining durability, precision, and versatility. From heavy-duty industrial use to delicate material finishing, it delivers outstanding results that save both time and cost. As I've experienced firsthand, once you switch to a brazed diamond wheel, it's hard to go back to traditional alternatives.

If you're seeking a professional solution for your grinding and cutting needs, QuanZhou JianYue Diamond Wheel Co., LTD is your trusted partner. Their expertise and dedication to quality make them a leading manufacturer in this field.

👉 For more details or to request a quotation, please contact us today!